Bursting strength is a critical characteristic used to evaluate the tensile strength of materials. This measurement involves applying increasing internal force until the material fails. The resulting magnitude of pressure at failure is then used to indicate the bursting strength of the material.

Understanding bursting strength is essential for various industries, including manufacturing, where materials are exposed to internal pressure. This understanding helps in selecting appropriate materials for specific applications and ensuring the safety of products.

- Factors such as material properties, thickness, and manufacturing processes can significantly influence bursting strength.

- Rigorous testing methods are employed to faithfully determine bursting strength, yielding valuable data for material selection and product design.

Examining Package Integrity with a Bursting Strength Tester

Ensuring the durability of your packages is paramount for safe and undamaged delivery. A bursting strength tester provides a vital tool to evaluate the capacity of your packaging materials under pressure. This instrument simulates real-world conditions by applying graduated force until the package breaks. The results yield valuable data about the capabilities read more of your chosen packaging materials, allowing for informed decisions to enhance overall package integrity.

Pushing Past Limits

Burst performance, often overlooked, is a critical aspect of material analysis. It measures the ability of a material to withstand internal stress before deterioration. Unlike tensile strength, which focuses on stretching, burst performance evaluates the material's capability to handle forces applied inward. This ensures a more holistic understanding of a material's overall strength and suitability.

Understanding burst performance is significantly relevant in applications where materials are subjected to internal forces, such as tanks. By determining a material's burst performance, engineers can develop more robust products that can effectively handle the expectations of their intended use.

Precise Determination of Material Burst Point

Determining the burst point of a material is vital for ensuring its reliability in applications where it is subjected to tension. This threshold represents the maximum load that a material can withstand before failure. Accurate determination of this burst point enables engineers to engineer safe and reliable structures and components. Analytical methods are employed to determine the burst point, utilizing careful evaluation of material properties, shape, and loading conditions.

Furthermore, understanding the parameters that determine the burst point is essential. These factors can include material composition, temperature effects, existing stresses, and force rate. By studying these factors, engineers can optimize the burst point performance of materials, leading to safer and more efficient designs.

Evaluating Material Resistance with Burst Strength Analysis

Burst strength analysis serves as a fundamental method in evaluating the resistance of materials to yielding. This process involves subjecting a material sample to an constantly rising internal pressure until it bursts. By measuring the maximum pressure at which this occurs, engineers can calculate the burst strength of the material, providing valuable insights into its durability under extreme pressures.

Understanding a material's burst strength is critical in many applications, particularly those dealing with high-pressure systems, containers, and other structural components. This evaluation helps ensure the safety and reliability of these systems by identifying potential weaknesses and guiding the selection of appropriate materials for specific requirements.

Enhancing Design with Reliable Burst Strength Data

Designing robust and durable products necessitates precise understanding of material properties. Burst strength, a crucial metric indicating a material's resistance to rupture under internal pressure, plays as a fundamental factor in ensuring product safety and performance.

Obtaining reliable burst strength data is paramount in optimizing design choices. Through rigorous testing utilizing standardized methods, engineers can establish the precise burst strength of various materials at different conditions.

This knowledge empowers designers to choose materials adequate of withstanding expected operational pressures, ultimately causing to more robust and reliable products.

By utilizing reliable burst strength data into the design process, engineers can mitigate the risk of product failure, guaranteeing enhanced safety and performance for a wider range of applications.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Robert Downey Jr. Then & Now!

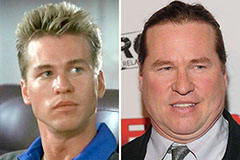

Robert Downey Jr. Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now!